TO CONVERT, OR NOT TO CONVERT?

THE R12 vs R134a DEBATE!

Author: Andre Clemente, Founder of New Old Cars, LLC ©

609 EPA licensed (Mobile Vehicle Air Conditioning)

Last updated: June 7, 2022

Tempted to convert your old car’s air conditioning system from R12 to R134a?

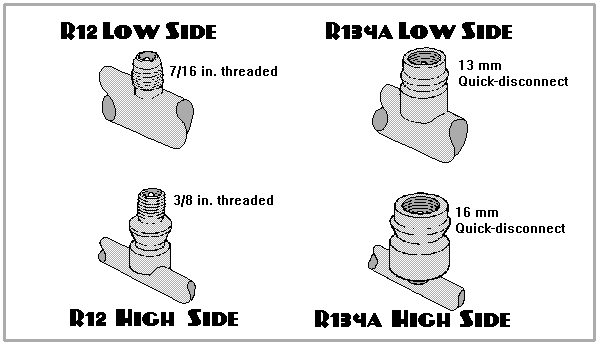

Before you do, first things first: it’s possible your car has already been converted from R12 to R134a, and you don’t even know it. To determine whether or not your system has been converted, just look at the service port fittings. R12 has threaded fittings (left) and R134a uses quick disconnect fittings (right).

However, if you want to go the extra mile in preserving your car’s originality and value (and you have additional money to spend) there a plenty of reasons to avoid doing this conversion.

Understand that R12 has its advantages. R12 can blow 6 to 7 degrees cooler than R134a and is 15% more efficient. R134a systems require larger condensers and higher operating pressures than R12 systems because R134a doesn’t have as high of a heat transfer rate as R12 (which has a heavier molecular size than R134a). As a result, a perfectly functioning R12 system will blow colder and reduce temperatures faster than a system that was converted to R134a. This is especially true in abnormally high ambient temperatures and/or high humidity.

For the people who claim that their A/C “blows colder” after converting from R12 to R134a, this was only because their R12 system was malfunctioning or had a leak, so of course the new system will appear to “blow colder” after an overhaul. Unlike American cars of the time (with large A/C components), many older European vehicles came with systems that were simply too small to be effective at cooling on a hot day (with their undersized condensers and tiny engine bays). Converting to R134a will NOT fix this problem any more than restoring your factory R12 system.

Don’t be mistaken: a modern R134a system will outperform a 30-year-old R12 system. This is simply a comparison of a solid running R12 system and an R134a conversion.

Below are other reasons why many decide NOT to convert from R12 to R134a:

1. R134A is more hygroscopic than R12, so it is more prone to moisture absorption. This requires tighter seals and connections, as well as increased maintenance. Also, since R134a has a smaller molecular size, it is more prone to leaks than R12.

2. PAG oil (Polyalkylene Glycol, a lubricant) comes standard in R134a cans, and this oil is not compatible with R12. If the R12 isn’t 100% flushed out of the system during a conversion, the newly introduced PAG oil will eventually turn into a gelatin-like substance, foregoing its ability to lubricate (PAG oil does not tolerate chlorine, which is found in R12).

3. Not every system is converted from R12 to R134a as thoroughly as others. Some backyard mechanics or shady shops take short cuts and don’t replace all the seals during a conversion, for example. PAG oil does not comply with R12 seals, dramatically reducing the life of the seals and resulting in leaks.

SO WHY DO PEOPLE PERFORM THE CONVERSION?

Converting your old car to R134a was so heavily endorsed in the past (and still is) because it is better for the environment. It is not ozone-depleting, unlike R12. But the real reason people do it is for cost and convenience. At $50+ a can, R12 is expensive and hard to find. You also need to show proof of a 609 EPA license before you can purchase any, forcing non-licensed owners to bring their vehicles to a licensed shop (going against the satisfaction of servicing their old car by themselves). That licensed shop needs to be equipped to service R12, and many aren’t. Add to the fact that R134a conversion kits are relatively inexpensive, and you can see why most people don’t hesitate to convert their cars.

One could argue that fewer and fewer shops are capable of servicing R12, but that depends on where you look. There has been an increased demand in restoring cars to factory original condition (with original A/C systems) and many vintage restoration shops are purchasing, restoring, and maintaining both R12 cars and R12 recovery equipment. Yes, it is a hassle to bring your car to these types of shops if they aren’t local, but once you have a perfectly functioning R12 system, it will require less maintenance than a “converted” R134a system, as well as blow colder, reach temperature faster, and maintain the originality of the car. Add to the fact that many R134a conversions are improperly done (resulting in issues), and you can see why an original, unmodified R12 system is desirable to both enthusiasts and collectors.

So do your research as to whether or not converting to R134a is the best option for you!

Question: I read somewhere online that, given two identical vehicles, each with the same amount of refrigerant, the vehicle with R134a has the ability to extract more heat from the system than an identical vehicle using the same amount of R12. Is this true?

Answer: Not true. Plus, an R134 converted system would never have the same amount of refrigerant as the original R12 system. A system converted to R134a can only be charged to roughly 80% capacity of the original R12 system. Therefore, the R12 system will blow colder than an R134a converted system of the same car.

Why the lower capacity? R134a requires larger compressors and larger heat exchangers than R12, so performing a conversion while retaining the factory R12 compressor/heat exchanger means you can only fill the system to roughly 80% capacity.

For example, if your system originally had 34 oz of R12, then your newly converted R134a system will only have 27 oz (34 x .80 = 27.2).

AVOID THE DIY RECHARGE CAN!

Is your R134a system not blowing as cold as it should? Think it just needs a top off? Maybe you’ll just head to the auto parts store and purchase an A/C recharge kit? Hold it right there!

Read why you should avoid using a DIY recharge kit to service your car’s air conditioning system!

Author:

Andre Clemente, Founder of New Old Cars, LLC ©

609 EPA licensed (Mobile Vehicle Air Conditioning)

Article last updated: June 7, 2022

Additional Article Sources:

Gilles, Tim. Automotive Service: Inspection, Service, Repair – 4th Edition. Delmar, Cengage Learning, 2012. Print

…and many more! NOC takes incredible pride in posting only the most accurate information with the help of credible sources. Now, because some links are no longer active, not all sources are posted here. These links have been removed from the source’s website for unknown reasons. However, NOC downloads and retains all sources used to stand by every statement in this article. This is done for all articles on our website, and NOC is happy to share this information with the public. Your trust is our number one priority.